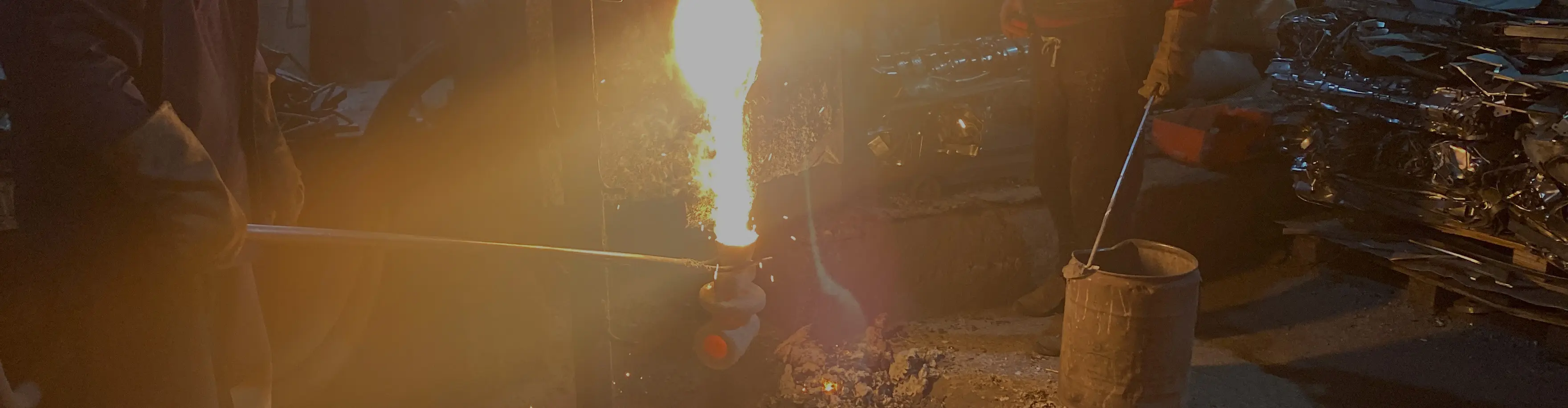

Investment Casting A Precision Casting Method

Investment casting, or lost wax casting, is indeed a remarkable process with a rich history and a wide array of modern applications. Here's a brief overview of the process and its benefits, as you've mentioned:

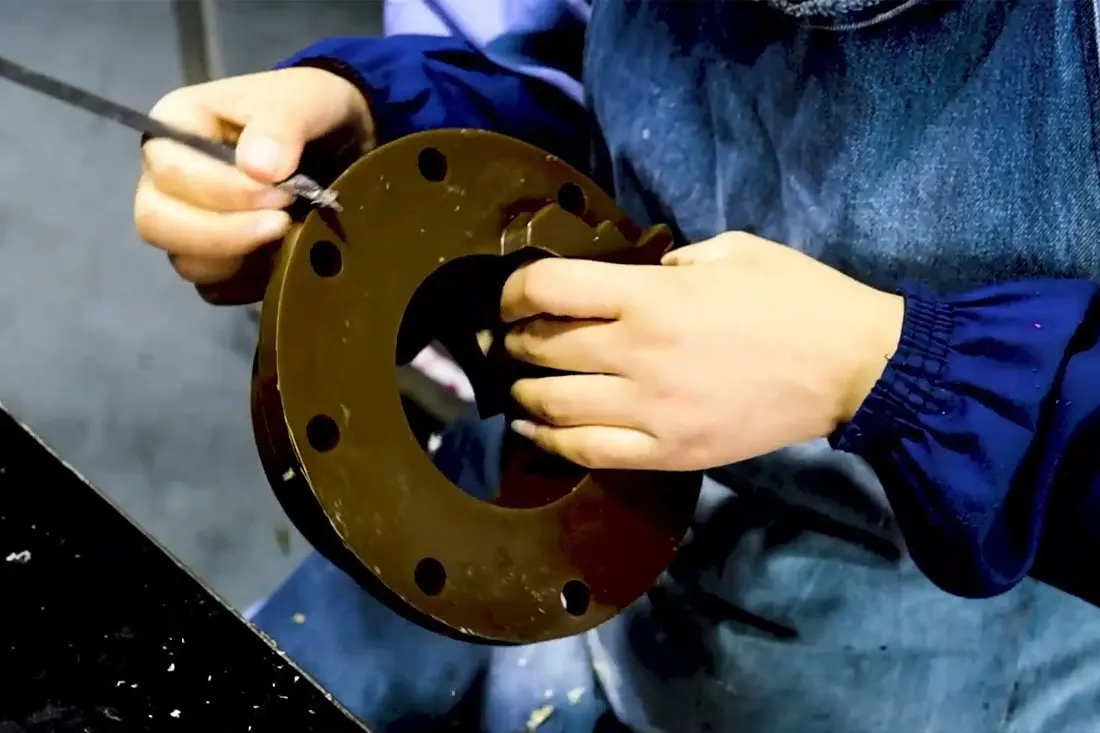

1. Precision and Detail: The use of wax patterns allows for the creation of parts with high precision and intricate details. The ceramic shell mold captures these details when the wax is removed, ensuring that the final cast part is a close replica of the original pattern.

2. Versatility in Materials: Investment casting is not limited to a few metals; it can be used with a variety of metals and alloys. This versatility is crucial for industries that require specific material properties for their components.

3. Efficiency and Cost-Effectiveness: The process is well-suited for mass production due to its automation capabilities. It can produce a large number of identical parts with minimal variation, which is cost-effective for manufacturers.

4. Applications: Investment casting is used in several industries where precision and complexity are required. In aerospace, it can be used for turbine blades and aircraft components. In the medical field, it's used for prosthetics and surgical instruments. The automotive industry also benefits from investment casting for parts like engine components and intricate decorative pieces.

5. Environmental Considerations: While investment casting offers many advantages, it's also important to consider the environmental impact. The process can be energy-intensive and may produce waste materials that require proper disposal or recycling.

6. Quality Control: Due to the precision of the process, quality control is often easier in investment casting compared to other casting methods. This can lead to fewer defects and less waste from rejected parts.

7. Design Freedom: The ability to create complex geometries without the need for draft angles or other manufacturing constraints gives designers more freedom to innovate.

Investment casting is a testament to the combination of ancient techniques with modern technology, resulting in a manufacturing process that is both efficient and capable of producing high-quality, complex parts. It's a valuable tool in the arsenal of modern manufacturing, particularly for industries that demand precision and performance.