In the intricate world of metalworking, precision casting stands out as a pivotal technique that enables manufacturers to create complex shapes with remarkable accuracy and minimal waste. Renowned industry expert, Dr. Amelia Rojas, a leading authority in precision casting technologies, emphasizes the importance of mastering this process: "Achieving perfection in precision casting requires not just skill, but an unwavering commitment to technique and detail." This underscores the significance of understanding the nuances involved in precision casting to ensure optimal results every time.

As industries demand higher quality and more intricate designs, the need for precision casting becomes increasingly pronounced. Techniques and methods have evolved, providing craftsmen with the tools they need to push the boundaries of what is possible. Whether you are a seasoned professional or a newcomer to the field, integrating effective tips into your precision casting practices can greatly enhance the quality of your outcomes. Through careful attention to detail, the right materials, and adherence to best practices, anyone involved in this field can achieve the perfect results that define excellence in precision casting.

Precision casting, also known as investment casting, is a manufacturing process that allows for the creation of intricate and high-accuracy metal parts. This method is particularly prized for its ability to produce components with complex geometries and smooth surface finishes, often eliminating the need for extensive post-processing. As per a market analysis report by the Global Industry Analysts, the global precision casting market is projected to reach approximately $16 billion by 2026, underscoring its significance in various industries including aerospace, automotive, and dental manufacturing.

In the aerospace sector, precision casting is instrumental in producing lightweight yet durable components necessary for enhancing fuel efficiency and performance. For instance, the Federal Aviation Administration highlights that advanced casting techniques can reduce aircraft weight by up to 20%, contributing to significant cost savings over the lifespan of an aircraft. Similarly, in the automotive industry, precision casting allows for the manufacturing of intricate engine components that are not only lighter but also more robust, which supports the ongoing trend towards electric vehicles that demand higher efficiency and performance standards.

With ongoing advancements in materials science and casting technologies, the precision casting process continues to evolve, providing even more innovative solutions tailored to meet the evolving demands of today’s industries.

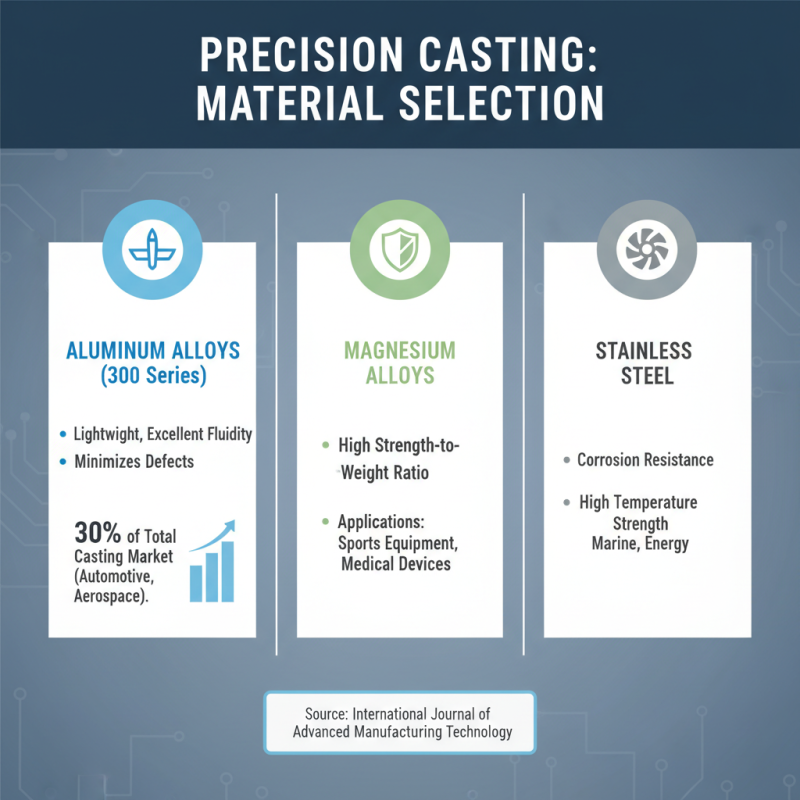

When considering precision casting, material selection plays a pivotal role in achieving optimal results. Key alloys, such as aluminum, magnesium, and stainless steel, are commonly used due to their distinct attributes that cater to various applications. For instance, aluminum alloys, particularly those in the 300 series, are favored for their lightweight characteristics and excellent fluidity, which minimize defects during casting. According to a report by the International Journal of Advanced Manufacturing Technology, aluminum casting accounts for nearly 30% of the total casting market, underscoring its importance in industries ranging from automotive to aerospace.

Magnesium alloys stand out for their superior strength-to-weight ratio, making them ideal for lightweight structures. A study highlighted in the Journal of Materials Processing Technology indicates that precision cast magnesium parts can achieve up to 75% weight reduction compared to their steel counterparts, which is crucial in sectors such as automotive and aviation where weight savings directly impact energy efficiency. Additionally, the versatility of stainless steel alloys, known for their corrosion resistance and mechanical strength, makes them indispensable in applications requiring durability and longevity. Reports project an annual increase of about 6% in the demand for stainless steel castings, reflecting their critical role in industrial practices.

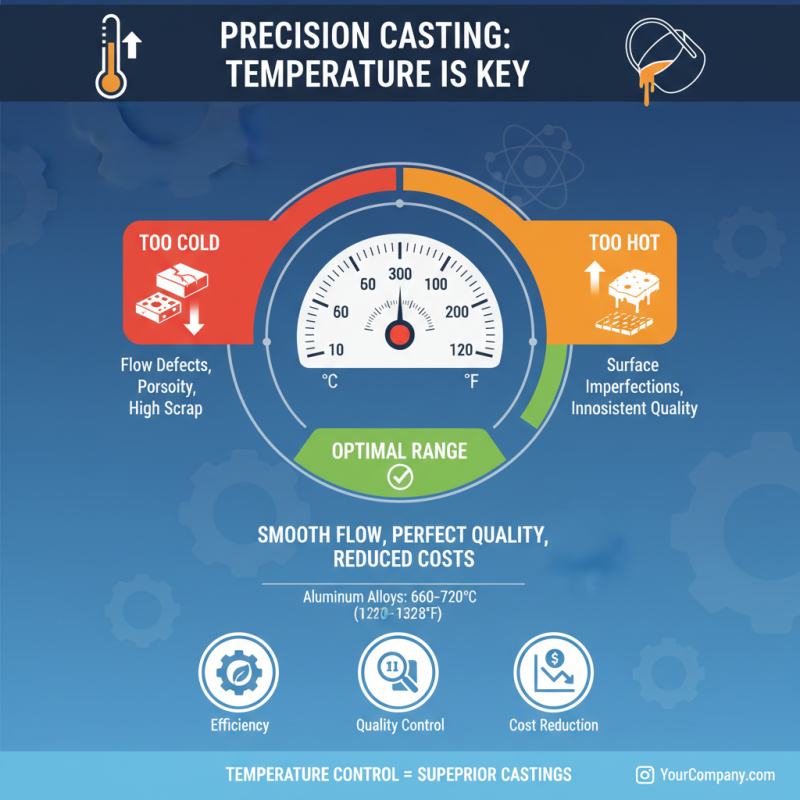

Temperature control plays a pivotal role in the precision casting process, directly influencing the quality and outcomes of cast products. According to industry reports, maintaining the optimal melting temperature for various alloys is essential to avoid defects such as porosity and surface imperfections. For example, aluminum alloys typically require a melting temperature between 660°C to 720°C (1220°F to 1328°F) to ensure a smooth flow into molds. Deviating from these temperatures can lead to inconsistent product quality, ultimately increasing scrap rates and production costs.

Moreover, the cooling rate after pouring is equally crucial as it affects the microstructure and mechanical properties of the final casting. A study published in the Journal of Materials Processing Technology highlighted that controlled cooling can improve tensile strength by up to 20%, while reducing residual stresses that might warp the cast piece. Proper insulation of molds and post-casting heat treatment techniques are among the best practices recommended to achieve precise temperature control. Ultimately, embracing rigorous temperature management strategies can significantly enhance productivity and result in high-quality castings that satisfy the stringent demands of industries such as aerospace and automotive.

Measuring tolerances and surface finish are crucial elements in precision casting, ensuring that the final product meets the desired specifications. Accurate measurement of tolerances begins with the selection of appropriate tools and techniques that can capture minute variations in dimensions. Instruments such as calipers, micrometers, and coordinate measuring machines (CMM) are commonly used in this process. Maintaining a consistent approach during measurement and calibrating these tools regularly enhances reliability, helping manufacturers to achieve tighter tolerances that can significantly influence the performance and longevity of the cast components.

Surface finish is another vital aspect that can impact the functionality and aesthetic of the cast parts. The finish can be evaluated through several methods, including visual inspection, roughness measurements with a profilometer, and comparing against established surface finish standards. Techniques such as sandblasting, polishing, or utilizing specialized coatings can improve surface quality and reduce defects. By implementing stringent quality assurance protocols and conducting regular assessments, precision casting operations can not only enhance product performance but also minimize waste and rework.

Precision casting is a sophisticated process that can yield high-quality components when executed correctly. However, defects can arise, impacting the integrity and functionality of the final product. Common defects include surface imperfections such as roughness and porosity, which can occur due to improper mold preparation or inadequate melting and pouring techniques. To identify these issues early, manufacturers should conduct regular inspections and utilize advanced imaging technologies to monitor surface quality.

Prevention strategies play a crucial role in mitigating these defects. First, ensuring the molds are clean and appropriately coated can help achieve a smooth finish. Additionally, controlling the temperature during the melting and pouring processes is vital; excessive temperature can lead to oxidation and gas incorporation, while insufficient temperature may cause incomplete filling of the mold. Implementing strict quality control measures, such as calibrating equipment and training staff on best practices, further enhances the precision casting process, minimizing the chances of defects and producing consistently excellent results.