The Investment Casting Process has long been regarded as a cornerstone in the manufacturing of precision metal parts, offering unparalleled accuracy and detail. Renowned expert in the field, Dr. Emily Carr, once stated, "Mastering the Investment Casting Process is essential for producing components that not only meet but exceed industry standards." This highlights the critical nature of adeptly navigating the complexities of investment casting to achieve superior results.

As industries continue to demand higher precision and efficiency, mastering the Investment Casting Process becomes increasingly vital. This method allows for intricate designs and excellent surface finishes, making it ideal for sectors such as aerospace, automotive, and medical device manufacturing. By honing the skills involved in the investment casting technique, manufacturers can significantly reduce waste and production costs while maintaining the integrity and performance of their components.

In an era where technological advancement is paramount, the Investment Casting Process stands out as a reliable and innovative approach for fabricating metal parts. Understanding and optimizing this process equips manufacturers with the tools necessary to thrive in a competitive landscape while delivering high-quality products that fulfill stringent requirements.

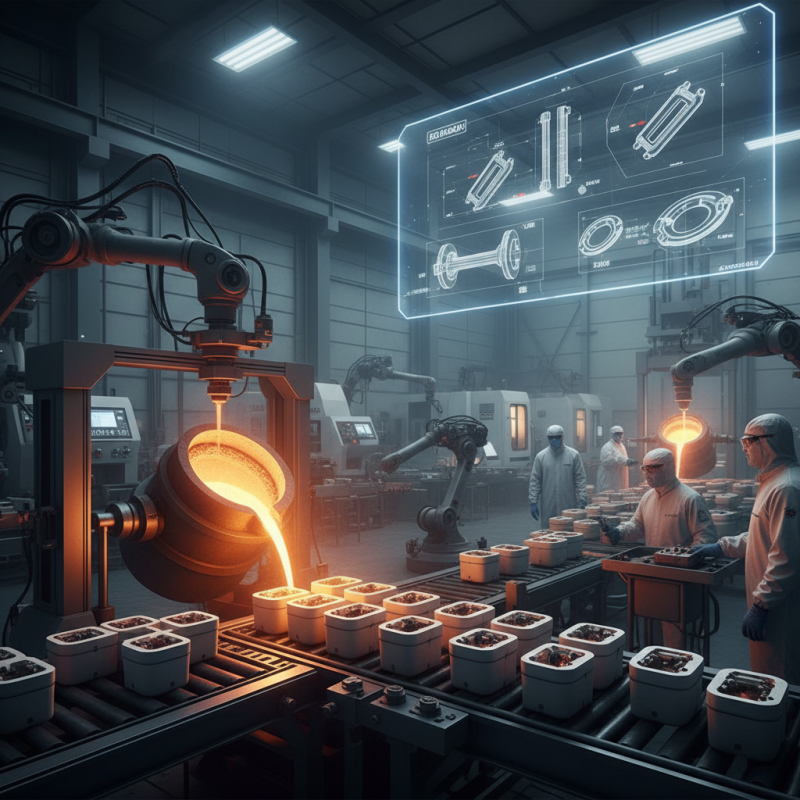

Investment casting, also known as lost-wax casting, is a precision manufacturing process that enables the creation of complex metal parts with excellent dimensional accuracy and surface finish. In this method, a wax pattern is coated with a ceramic shell, which is then heated to remove the wax and harden the shell. According to a recent report by the Investment Casting Institute, this technique can achieve tolerances as tight as ±0.005 inches, making it ideal for intricate designs typically seen in the aerospace, automotive, and medical industries.

The applications of investment casting are vast and varied. For instance, it is widely used in producing turbine blades for jet engines, where performance and precision are critical. The global investment casting market was valued at around $16.6 billion in 2020 and is projected to grow at a CAGR of 5.6% from 2021 to 2028, driven by increasing demand in high-performance sectors. Technical advancements in the process, coupled with the growing trend of lightweight materials in manufacturing, further enhance the capabilities of investment casting, allowing for innovations in product design and functionality. This positions investment casting as a pivotal process in the manufacturing landscape, catering to the needs of high-tech industries while maintaining cost-effectiveness.

Investment casting, also known as lost-wax casting, is a well-established manufacturing technique known for producing highly accurate metal parts. The essential materials used in this process play a critical role in ensuring the quality and precision of the final products. The primary materials include the pattern material, typically wax or polymer, which is molded into the desired shape. In a recent industry report, it was noted that the investment casting market is projected to grow at a CAGR of 5.6% from 2021 to 2028, driven largely by the increased demand for precision-engineered parts in sectors such as automotive and aerospace.

The refractory materials used for making the investment casting molds are equally important. These molds are typically constructed from high-grade ceramics, which can withstand extreme temperatures during the metal pouring process. According to research, the use of advanced ceramics not only increases the mold's durability but also enhances surface finish and dimensional accuracy, which are paramount in achieving high-quality castings.

Tips: When selecting materials for investment casting, consider the thermal expansion properties and compatibility with the molten metal to be used. Additionally, ensure that the wax or polymer patterns are free from defects to avoid inconsistencies in the mold. Investing in high-quality refractory materials can significantly improve the performance of your casting process, leading to better yield and reduced rework rates.

Creating high-quality investment casting molds is a crucial step in the investment casting process, directly influencing the precision and surface finish of the final metal parts. To master this process, one should begin by selecting the right materials for the mold, often opting for silica sand or specialized ceramics, which provide excellent thermal properties and reusability. According to the "Investment Casting Market Analysis" report by MarketsandMarkets, the investment casting market is projected to reach $24.61 billion by 2025, underscoring the importance of precision in this sector.

The mold creation process itself includes several key stages. First, a pattern of the desired part is made, typically from metal or a polymer, which serves to form the cavity of the mold. This pattern is then coated with a thin layer of ceramic slurry, often reinforced with sand, to build a robust mold shell. After the mold has cured, it is heated to remove the pattern and harden the shell, resulting in a precise mold ready for pouring molten metal. According to a study from the American Foundry Society, this method can achieve tolerances as tight as ±0.005 inches, making it ideal for intricate designs and high-performance applications. The accuracy of the mold creation process is essential as it directly correlates with the yield and quality of the final casted parts.

Precision in metal part production through the investment casting process hinges on a few key techniques. First and foremost, the quality of the initial wax pattern plays a critical role in achieving high accuracy in the final product. Using advanced 3D printing technology for creating wax patterns can significantly enhance the detail and dimensional stability of the patterns. This technology allows for intricate designs and tighter tolerances, which ensures that the final metal parts closely match the intended specifications.

Another vital technique is the control of the mold-making process. Employing high-quality ceramics and optimizing the mold curing temperature can minimize defects such as shrinkage and warping. A well-controlled mold not only preserves the integrity of the mold shape but also contributes to uniform thickness in the casting, which further promotes consistency in the finished parts. Additionally, incorporating real-time monitoring during the pouring phase helps detect any anomalies, allowing for immediate adjustments to maintain precision throughout production. By integrating these techniques, manufacturers can significantly improve the accuracy and reliability of their investment casting processes.

Quality control is a critical aspect of the investment casting process, ensuring that metal parts meet the required specifications and standards. The investment casting industry is rapidly evolving, with a projected market size expected to reach approximately $26.6 billion by 2028, growing at a CAGR of 5.2% from 2021 to 2028, according to a report by Grand View Research. This growth emphasizes the increasing demand for precision-engineered components across various sectors, including aerospace, automotive, and medical.

To maintain high-quality standards, several key control measures are implemented throughout the investment casting process. These include thorough inspections of raw materials, detailed monitoring of the casting environment, and adherence to standardized procedures. For example, a study published in the Journal of Materials Engineering and Performance highlights that the dimensional accuracy of investment cast parts can achieve tolerances as tight as ±0.005 inches (±0.127 mm), contingent upon rigorous quality checks. Furthermore, ensuring proper wax patterns and consistent temperature control during the melting process plays a vital role in minimizing defects such as porosity and dimensional deviations.

Statistical process control (SPC) is also widely adopted to track and control the quality of the investment casting output. By utilizing tools such as control charts and process capability analysis, manufacturers can identify variations and implement corrective actions proactively. According to ASM International, companies employing such quality control methods have reported a decrease in defect rates by as much as 30%, ultimately enhancing customer satisfaction and competitiveness in the market. These measures not only ensure the integrity of the final product but also contribute to overall cost savings and efficiency within the production cycle.