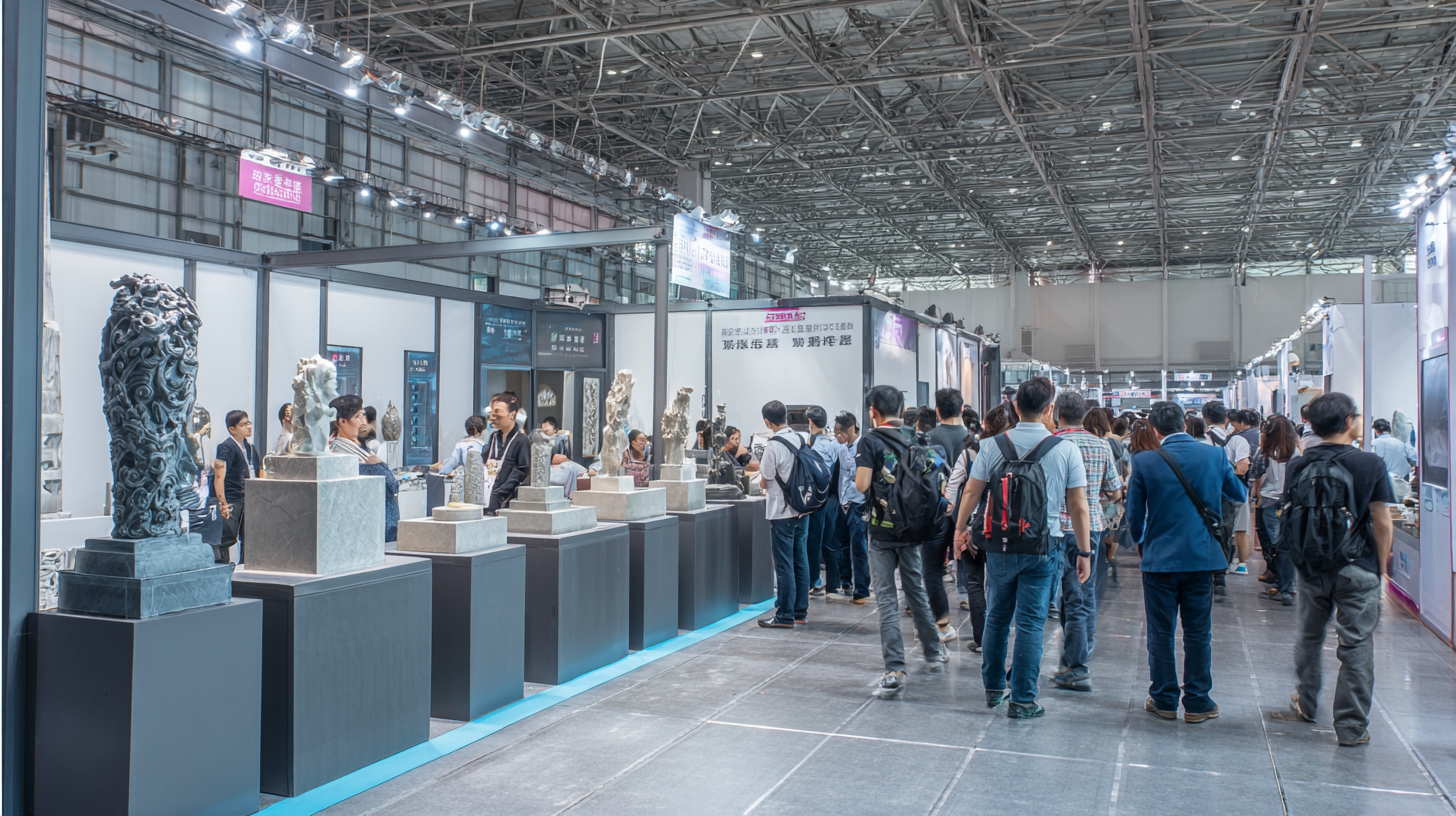

The 138th Canton Fair in 2025 presents a unique opportunity to delve into the latest innovations in Lost Wax Casting, a venerable manufacturing technique that has evolved significantly over the years.

This event not only serves as a platform for showcasing cutting-edge technologies and products but also fosters dialogue among industry experts and enthusiasts.

As the demand for precision and intricate designs continues to rise across various sectors, including jewelry, art, and automotive industries, the advancements in Lost Wax Casting take center stage. Attendees can expect to gain invaluable insights into emerging trends, sustainable practices, and the integration of digital technologies that are reshaping the landscape of this age-old craft.

By exploring these innovations, the Canton Fair highlights the essential role of Lost Wax Casting in driving the growth of various industries, paving the way for a future that honors tradition while embracing modernity.

This event not only serves as a platform for showcasing cutting-edge technologies and products but also fosters dialogue among industry experts and enthusiasts.

As the demand for precision and intricate designs continues to rise across various sectors, including jewelry, art, and automotive industries, the advancements in Lost Wax Casting take center stage. Attendees can expect to gain invaluable insights into emerging trends, sustainable practices, and the integration of digital technologies that are reshaping the landscape of this age-old craft.

By exploring these innovations, the Canton Fair highlights the essential role of Lost Wax Casting in driving the growth of various industries, paving the way for a future that honors tradition while embracing modernity.

The 138th Canton Fair in 2025 is set to showcase groundbreaking innovations in lost wax casting, a process that has evolved significantly over the years. Recent industry reports indicate that the global market for lost wax casting is poised to grow at a CAGR of 5.6% from 2023 to 2028, driven by advancements in technology and expanding applications across various sectors including aerospace, automotive, and jewelry production. The fair will provide an excellent platform for exhibitors to present cutting-edge techniques that enhance precision and reduce waste, such as 3D printing of wax patterns and automated casting systems.

One notable trend in lost wax casting is the increasing use of environmentally friendly materials, which has become a priority for manufacturers striving for sustainability. According to a 2022 study by the International Journal of Advanced Manufacturing Technology, the adoption of sustainable practices in lost wax casting can result in a 20% reduction in material costs and up to 30% lower energy consumption. Exhibitors at the Canton Fair will undoubtedly highlight these innovative approaches, showcasing their commitment to eco-friendly manufacturing while still meeting the high standards of quality and precision expected in the industry.

The 138th Canton Fair in 2025 highlighted significant advancements in the lost wax casting technique, showcasing how traditional craftsmanship is evolving into a realm of innovative designs and sustainable practices. Artists and manufacturers are increasingly experimenting with new materials and digital technologies, creating intricate metalwork that reflects contemporary aesthetics while maintaining age-old techniques. Exhibitors presented a range of metal sculptures and functional art pieces that not only serve as decorative items but also tell unique stories grounded in heritage.

Emerging trends in metalwork emphasize the integration of eco-friendly practices into production processes. Many artisans are prioritizing sustainable sourcing and recycling of metals, alongside the use of non-toxic coatings. Additionally, workshops and demonstrations at the fair provided insights into how modern technology, such as 3D printing, is enhancing the precision and creativity of lost wax casting. These innovations are attracting a new generation of artisans keen to blend traditional craftsmanship with cutting-edge techniques, ultimately redefining the future of metalworking and craftsmanship in the industry.

At the 138th Canton Fair 2025, the lost wax casting industry is set to showcase groundbreaking innovations driven by technology. Advances in computer-aided design (CAD) and additive manufacturing have significantly influenced the casting process, enabling manufacturers to produce more intricate and precise designs than ever before. According to a recent report by MarketsandMarkets, the global investment casting market is projected to reach $23.23 billion by 2027, with a compound annual growth rate (CAGR) of 4.8%. This growth is largely attributed to the integration of technology that enhances efficiency and reduces waste in the production process.

The impact of technology on lost wax casting is evident in the development of faster prototyping techniques that allow for more rapid iteration and testing of designs. Techniques such as 3D printing of patterns have become commonplace, reducing lead times and costs associated with traditional methods. A study by Deloitte found that companies adopting advanced manufacturing practices, including lost wax casting technologies, reported a productivity increase of 16%, showcasing how essential these innovations are for competitive advantage in the industry. The Canton Fair serves as a pivotal platform for industry leaders to exchange ideas and further harness technology to maximize the potential of lost wax casting, ultimately benefiting a range of sectors from aerospace to jewelry production.

The 138th Canton Fair 2025 presents a pivotal opportunity for companies engaged in lost wax casting, as it gathers a diverse array of industry experts and innovators under one roof. This ancient technique, known for its precision and detail, is witnessing a resurgence driven by advancements in technology and changing market demands. As manufacturers seek to optimize production processes and enhance product quality, lost wax casting is becoming increasingly relevant across various sectors, including aerospace, automotive, and jewelry.

In the global economy, the demand for customized and high-performance components is rising, creating substantial market opportunities for lost wax casting. The ability to produce intricate designs with superior dimensional accuracy positions this method as a competitive edge in manufacturing. Furthermore, as sustainability concerns grow, companies are innovating to improve material efficiency and reduce waste, aligning with global trends toward environmentally friendly practices. This confluence of market demands and technological advancements underscores the potential for lost wax casting to carve out a significant space in the global manufacturing landscape.

At the 138th Canton Fair, industry leaders gathered to explore innovative trends in lost wax casting, emphasizing the importance of networking and collaboration. This event has become a focal point for professionals interested in the latest advancements and applications of this traditional technique, which aligns with modern demands for precision and artistic excellence. Participants engaged in exchange sessions, fostering partnerships that could drive future developments in manufacturing and design.

The fair served as a platform for organizations to showcase their latest products and technologies while simultaneously building connections with potential partners and clients. This collaborative spirit was underscored by various forum discussions that highlighted the role of innovation in enhancing production efficiencies and sustainability. As companies strive to expand their global reach, the interactions and agreements formed during the event are likely to set the stage for significant strides in the industry moving forward.