Choosing the right casting pump parts is crucial for ensuring optimal performance in various industrial applications. These components play a vital role in determining the efficiency, reliability, and overall functionality of casting pumps. With the increasing demand for productivity and sustainability in manufacturing processes, the importance of selecting high-quality casting pump parts cannot be overstated. Properly designed and manufactured components contribute not only to the longevity of the equipment but also to reduced maintenance costs and operational downtime.

In the world of casting technology, the compatibility and performance of pump parts are linked to the specific requirements of the casting process, including flow rates, viscosity of the materials being pumped, and overall system design. Careful consideration must be given to factors such as material composition, wear resistance, and precision engineering. By understanding these elements, operators can make informed decisions that lead to enhanced performance and reduced risk of failure. Ultimately, investing time and resources into selecting the appropriate casting pump parts will pay dividends in terms of efficiency, productivity, and the successful outcome of critical casting operations.

Casting pumps are essential components in various industrial processes, particularly in foundries and metalworking. Their primary function is to transport molten metals, which requires utmost precision and reliability. According to a report by the American Foundry Society, proper functioning of casting pumps can enhance operational efficiency by up to 20%, significantly impacting production rates and reducing waste. Given that casting processes are often capital-intensive, even minor inefficiencies can lead to substantial financial losses.

In terms of functionality, casting pumps are designed to handle high temperatures and aggressive materials. This necessitates the use of high-quality pump parts that not only withstand extreme conditions but also provide durability over time. The performance of these pumps can be influenced by various factors, including design specifications, flow rates, and the materials used in their construction. A study by the International Journal of Applied Engineering Research indicated that the right selection of casting pump parts plays a critical role in maintaining optimal pump performance and longevity. Thus, investing in suitable parts is not just a matter of preference but a critical aspect of operational success in industries relying on casting technology.

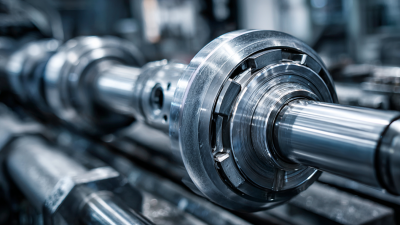

When it comes to casting pumps, the quality of the components significantly affects overall performance and efficiency. Key components such as the impeller, casing, and seals play pivotal roles in ensuring that the system operates smoothly. The impeller, for instance, is crucial for converting mechanical energy into fluid energy, enabling the movement of fluids through the pump. Its design and material selection can influence the flow rate and head pressure, making it essential to choose an impeller that aligns with the specific demands of the application.

Another vital component is the pump casing, which houses the impeller and provides a pathway for the fluid to flow. A well-designed casing minimizes fluid turbulence and reduces energy loss, thus enhancing the pump's efficiency. Additionally, seals are indispensable for preventing leaks and maintaining optimal pressure within the system. Proper sealing ensures that the integrity of the pumping operation is preserved, protecting both the pump and the surrounding environment. Selecting high-quality casting pump parts not only boosts performance but also extends the lifespan of the pump, reducing maintenance costs and downtime.

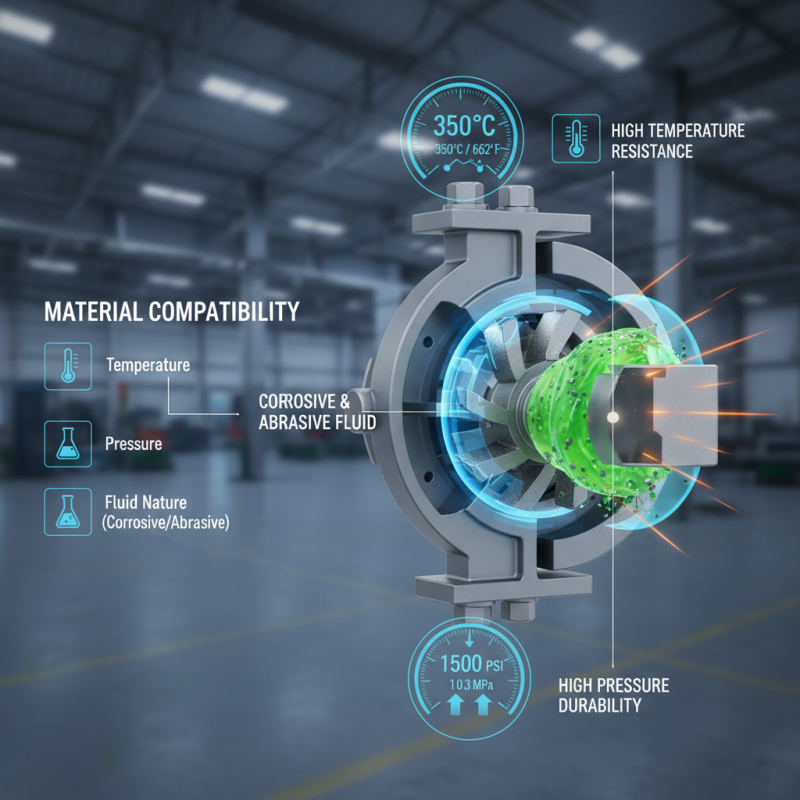

When selecting casting pump parts, several critical factors come into play to ensure optimal performance and reliability. First and foremost is material compatibility. Pump parts are often subjected to various operating conditions, including temperature, pressure, and the nature of the fluid being pumped. Choosing materials that can withstand these conditions is essential to prevent premature wear and failure. For example, corrosion-resistant materials may be necessary for pumps handling abrasive or corrosive liquids, while heat-resistant components are required for high-temperature applications.

Another key consideration is the design and fit of the components. Proper alignment and sizing of pump parts are vital for maintaining efficiency and reducing energy consumption. Mismatched parts can lead to increased vibrations, leaks, and, ultimately, mechanical failure. It's crucial to consult manufacturer specifications and ensure that all components are compatible with the existing system. Additionally, the performance characteristics of the pump parts, such as flow rates and pressure ratings, should align with the operational requirements of the system, contributing to sustained performance over time.

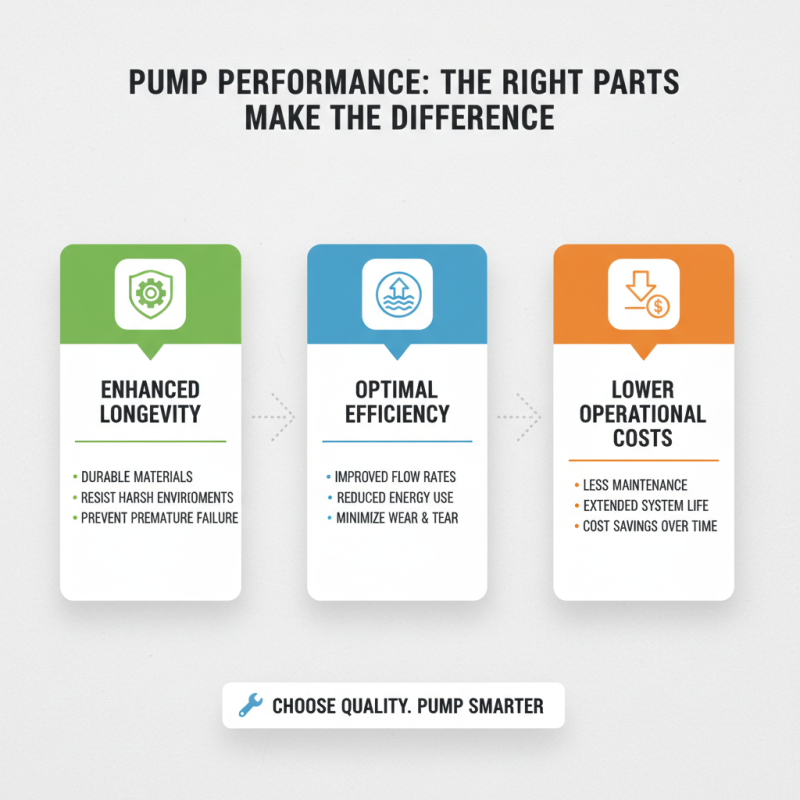

Choosing the right casting pump parts is crucial for ensuring that your pumping system operates at peak efficiency. High-quality parts significantly influence how well the pump performs under various conditions. For instance, components made from durable materials can withstand harsh environmental factors and prevent premature failure, thereby enhancing the system's longevity. Properly designed parts can also improve flow rates, reduce energy consumption, and minimize wear and tear, leading to lower operational costs over time.

Tips for selecting quality casting pump parts include consulting reliable manufacturers and suppliers who prioritize quality assurance in their production processes. It's essential to review specifications and compatibility with existing systems to ensure seamless integration. Additionally, consider investing in parts that come with warranties or guarantees, as this can serve as an indicator of their reliability and performance.

Regular maintenance and inspection of casting pump parts are equally important. Keeping an eye out for signs of wear and tear can help you identify potential issues before they escalate, ensuring that the pump continues to operate efficiently. By making informed choices about the parts you use and maintaining them properly, you can significantly enhance the overall performance of your casting pump system.

Improper selection of casting pump parts can lead to a range of issues that significantly affect operational efficiency and longevity. One common problem is cavitation, which often occurs when the wrong impeller or casing is chosen. When the impeller cannot adequately manage the fluid dynamics due to a mismatch in design or material, it can lead to vapor bubbles forming and collapsing, resulting in damage to the pump components and reduced performance.

Another frequent issue associated with improper parts selection is excessive wear and tear. If components are not made of suitable materials or have incorrect tolerances, they may wear down faster than anticipated. This can lead to increased maintenance costs, unexpected downtimes, and disruptions in production. Furthermore, using incompatible parts can affect the hydraulic performance of the system, leading to inefficient pumping and increased energy consumption, which further exacerbates operational costs. Making informed decisions regarding casting pump parts is crucial to avoid these pitfalls and ensure smooth, efficient operation.