Steel Investment Casting is a crucial manufacturing process in various industries, known for its ability to produce complex geometries with excellent precision and surface finish. According to a report by Markets and Markets, the global investment casting market is projected to reach approximately $22.93 billion by 2027, indicating a growing reliance on this method among manufacturers seeking both durability and cost-effectiveness in their components. This remarkable growth is driven by increasing demand in sectors such as aerospace, automotive, and oil and gas, where the robustness of steel cast products is essential.

Choosing the right Steel Investment Casting process for a specific project involves considering various factors, including component design, material specifications, and production volume. Industry professionals indicate that optimizing these factors can lead to significant improvements in product performance and overall manufacturing efficiency. With advancements in technology, including the use of computer-aided design (CAD) and 3D modeling, manufacturers can achieve unparalleled precision and reduce waste during the production phase, further enhancing the attractiveness of the process.

As the landscape of manufacturing continues to evolve, understanding the nuances of Steel Investment Casting becomes increasingly important. By carefully evaluating the available options, businesses can leverage this technology to meet their project requirements while maintaining competitive advantages in quality and cost.

Steel investment casting is a highly sophisticated and efficient manufacturing process used to produce intricate metal parts. This method involves creating a wax pattern that is coated with a ceramic shell. Once the shell hardens, the wax is melted away, leaving a precise cavity in the shape of the desired part. Molten steel is then poured into the cavity, solidifying to form the final cast component. Understanding these basic steps is crucial for selecting the right investment casting process for your project.

Tips for choosing the right process include evaluating the complexity of your design. Intricate designs with tight tolerances benefit from investment casting due to its high level of precision. Additionally, consider the volume of production; investment casting is most cost-effective for medium to high volumes. Finally, the type of steel required for your application should also be assessed, as different steel grades possess distinct properties that may affect performance.

Another key consideration is the post-casting finishing processes. Depending on the intended application, additional treatments may be necessary to enhance the part’s durability or appearance. Selecting the appropriate surface finish can greatly impact the functionality of the final product. Engaging with experienced professionals in the investment casting field can further guide your decision-making, ensuring that your steel components meet the highest standards of quality and performance.

When selecting the right steel investment casting process for your project, several key factors must be taken into account. One of the primary considerations is the complexity of the part design. According to research by the American Foundry Society, intricate geometries can often be produced more effectively through investment casting due to its capability to create tight tolerances and fine details. This process is particularly advantageous when creating components that require precise dimensions and excellent surface finishes.

In addition to design complexity, the type of steel used plays a critical role. Different steels have varying properties, such as strength, corrosion resistance, and machinability. For high-performance applications, using a steel alloy that meets the required mechanical properties is essential. Industry reports indicate that investing in high-quality materials and processes can enhance the longevity and reliability of the cast components, sometimes by up to 30%.

Tips: Always conduct a thorough material analysis to ensure the selected steel alloy aligns with your project’s performance requirements. Collaborating with experienced engineers can provide insights into the most suitable casting methods for your specific needs. Evaluate the total cost of ownership, factoring in not just the initial casting cost but also potential post-casting processing and maintenance.

| Casting Process | Material Type | Tolerance Level | Surface Finish | Production Volume | Lead Time |

|---|---|---|---|---|---|

| Investment Casting | Carbon Steel | ±0.5 mm | Ra 1.6 – 3.2 µm | Low to Medium | 4-6 weeks |

| Sand Casting | Alloy Steel | ±1.0 mm | Ra 3.2 – 6.3 µm | Medium to High | 6-8 weeks |

| Die Casting | Stainless Steel | ±0.2 mm | Ra 0.8 – 1.6 µm | High | 3-4 weeks |

| Centrifugal Casting | Mild Steel | ±0.7 mm | Ra 3.2 – 12.5 µm | Medium | 5-7 weeks |

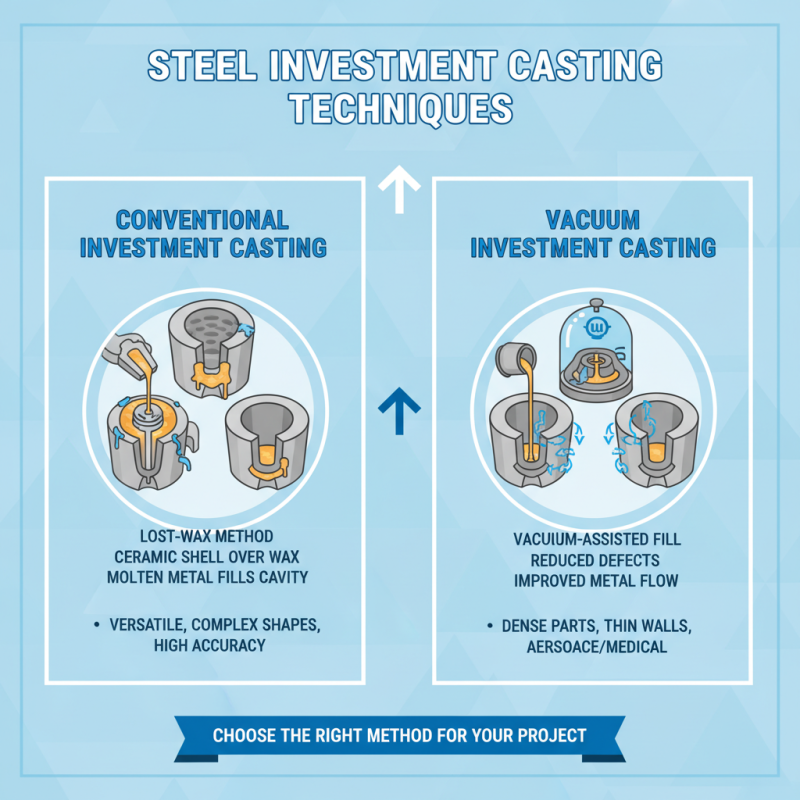

When selecting the appropriate steel investment casting technique for your project, it's essential to understand the different methods available. The most commonly used techniques include the conventional investment casting and the vacuum investment casting. Conventional investment casting, often referred to as lost wax casting, involves creating a wax pattern which is coated with a ceramic shell. Once the shell is hardened, the wax is melted away, allowing molten metal to fill the cavity. This method is highly favored for its versatility and ability to produce complex geometries with excellent dimensional accuracy.

On the other hand, vacuum investment casting utilizes a vacuum system to prevent defects during the metal pouring process. This technique minimizes gas entrapment and oxidation, resulting in superior surface finishes and enhanced mechanical properties in the final product. Vacuum investment casting is especially beneficial for intricate designs where precision is paramount. Choosing between these methods often depends on project requirements such as volume, material properties, and budget constraints. Understanding the nuances of each technique can guide you toward the best choice for achieving optimal results in your steel investment casting project.

When embarking on a project that requires steel investment casting, evaluating the material requirements is a critical first step. Different applications may demand varying levels of strength, corrosion resistance, and thermal stability, all of which can influence the casting process selected. For instance, components intended for high-stress environments may require materials with superior tensile strength and fatigue resistance, while those exposed to harsh chemicals might benefit from stainless steel options. Understanding these specific needs will guide you in choosing the most suitable alloy and process.

Tips: Always consult with your engineering team to assess the mechanical properties required for your components. Conducting a thorough analysis of the working environment and expected loads can significantly aid in selecting the right material. Furthermore, remember to consider post-casting processes, as certain materials may require additional treatments, such as heat treatment or surface finishing, to meet your project's specifications.

Keeping the end-use performance in mind, it is vital to balance cost with quality. While certain materials may be more expensive upfront, they could reduce maintenance costs over time. Analyze the lifecycle of the component and consider how material choices will affect overall project economics. Taking these steps ensures that you choose a steel investment casting process that aligns well with your project's material requirements.

When considering the steel investment casting process for a project, cost and time considerations play a pivotal role in determining the feasibility and success of the endeavor. According to industry reports, the initial tooling and setup for steel investment casting can require an investment ranging from $20,000 to $200,000, depending on the complexity of the part and the material specifications. These upfront costs can be a hindrance for projects with tight budgets, but the high level of precision and reduced post-processing need often justifies the initial financial outlay in the long run.

On the time front, the investment casting process generally offers a faster turnaround than traditional manufacturing techniques due to its ability to produce intricate shapes with minimal machining required. Reports indicate that typical lead times for investment casting can vary from four to twelve weeks, contingent on factors like the size of the order and the complexity of the design. By leveraging advanced technologies and careful planning, manufacturers can optimize production schedules to meet urgent project timelines without compromising quality. Thus, understanding these cost and time metrics is crucial for project managers aiming to choose the most appropriate steel investment casting process that aligns with both their budget and delivery targets.