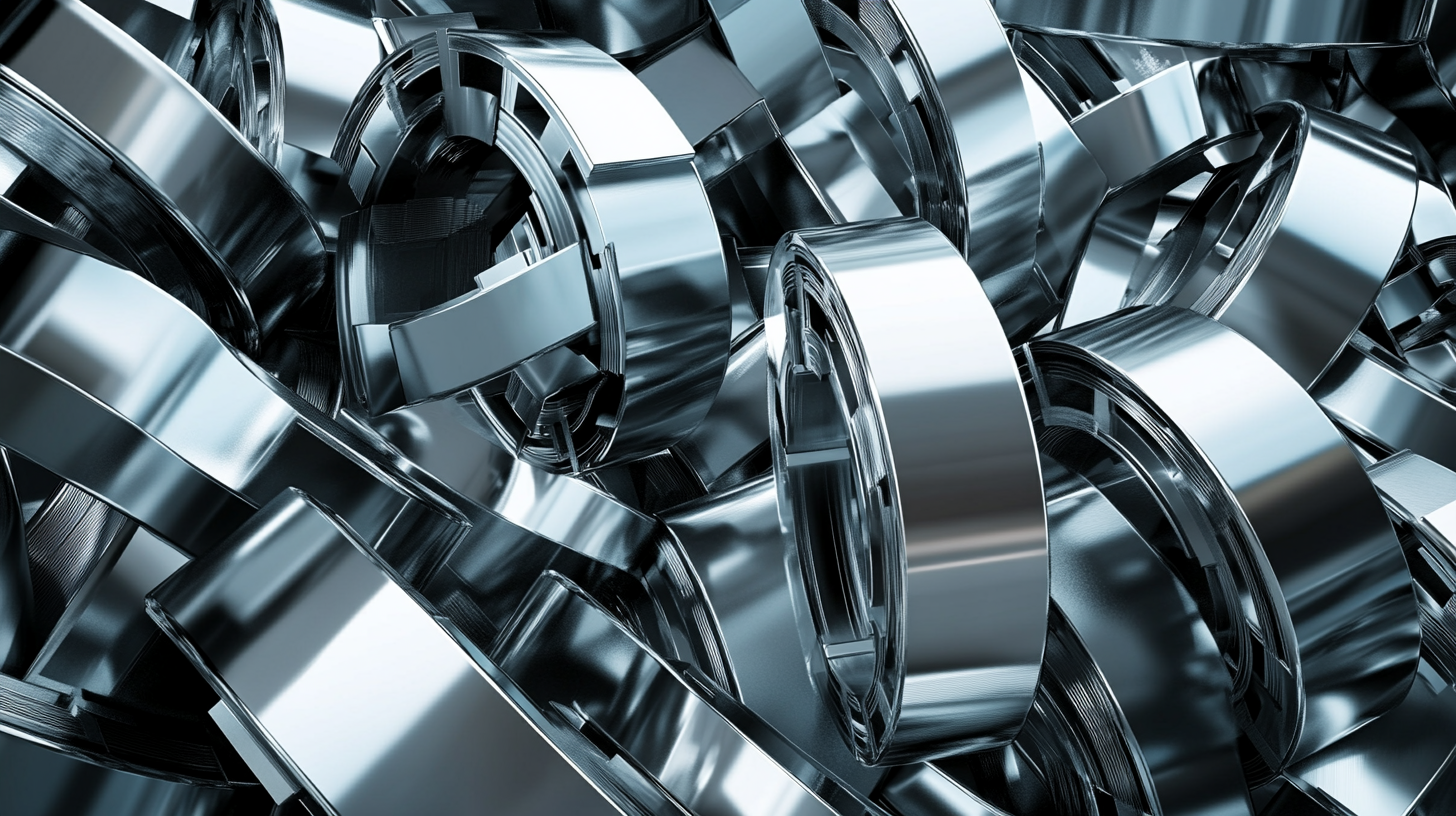

In today's interconnected world, the manufacturing sector plays a pivotal role in driving global economic growth, with China's manufacturing capabilities standing out significantly, particularly in the realm of metal parts. According to a report by Deloitte, China accounted for approximately 28% of the world's manufacturing output in 2020, a testament to its robust production infrastructure and skilled workforce. The metal parts manufacturing industry, as per the latest data from the American Foundry Society, is projected to reach a market size of $200 billion by 2025, emphasizing the increasing demand for precision-engineered components. This burgeoning sector not only caters to domestic needs but also enhances international supply chains, fostering innovation and cost-efficiency. As businesses worldwide seek reliable suppliers of high-quality metal parts, understanding the nuances of China's manufacturing edge becomes essential for unlocking global potential.

The rise of Chinese metal parts manufacturing is a significant global phenomenon, driven by various economic dynamics and trade relationships. Recently, the aluminum market has faced downward pressure due to oversupply concerns, particularly linked to a surge in production from China. This influx has implications not only for pricing but also for international trade balances, particularly affecting markets like India, where record levels of finished steel imports from China have raised alarms among domestic producers. This scenario underscores the intertwined nature of global metal markets and the influence of Chinese manufacturing.

China's strategy of utilizing extensive subsidies has further complicated these dynamics, fueling global trade tensions. As countries navigate the repercussions of these practices, industries worldwide must adapt to the realities of China's manufacturing dominance. From electric vehicles to aluminum and steel production, China's capability to scale and innovate continues to reshape the landscape, marking its position as a manufacturing superpower. The evolution of these market forces reflects broader economic transformations influencing trade equity and competitive practices on a global scale.

This pie chart represents the global share of metal parts manufacturing by region, highlighting the dominance of Chinese manufacturing in the sector.

China's prominence in the global metal parts manufacturing sector can be attributed to several key factors that fuel its competitive edge. According to a report by Smithers Pira, the country accounted for approximately 28% of the worldwide metal fabrication market in 2022, highlighting its significant role in supply chains across various industries. The combination of advanced technology, a robust labor force, and substantial investment in infrastructure enables Chinese manufacturers to produce high-quality metal components at scale and competitive prices.

Another driving force behind China's dominance is its relentless focus on innovation and automation. The Ministry of Industry and Information Technology reported that over 70% of metal parts manufacturers have adopted advanced manufacturing technologies, such as robotics and artificial intelligence, enhancing efficiency and reducing production costs. Furthermore, China's strategic initiatives, like the "Made in China 2025" program, emphasize upgrading its manufacturing capabilities, ensuring that it remains at the forefront of the metal parts production industry. This commitment to technological advancement not only increases production quality but also positions China as a go-to source for a diverse range of metal components, from automotive to aerospace applications.

The landscape of global manufacturing is rapidly evolving, and China's metal parts industry is at the forefront of this transformation thanks to continuous innovations in technology and process. Companies are leveraging advanced manufacturing techniques such as automation, artificial intelligence, and 3D printing, which not only enhance production efficiency but also reduce costs. This technological integration enables manufacturers to produce high-quality metal parts that meet the stringent requirements of various industries, from automotive to aerospace.

Moreover, process innovations are reshaping how metal parts are designed and manufactured. Techniques like precision casting and laser cutting allow for greater customization and complex geometries, giving Chinese manufacturers a competitive edge. By adopting lean manufacturing principles, companies can streamline operations and minimize waste, ensuring they deliver products faster while maintaining high standards. This commitment to innovation not only strengthens their market position but also elevates the overall quality of Chinese manufacturing on the global stage.

The Chinese manufacturing sector has long been recognized for its efficiency and scale, particularly in the production of metal parts. However, this impressive growth has not come without its challenges. One significant issue is the reliance on outdated technology and processes, which can hinder innovation and productivity. Many manufacturers find it difficult to adopt advanced manufacturing techniques due to the high initial costs and the need for skilled workers. This gap not only limits their competitiveness but also affects the overall industry’s potential on the global stage.

To address these challenges, investment in modernizing machinery and training the workforce is crucial. Collaborations with technology firms can facilitate the integration of automation and smart manufacturing solutions, paving the way for a more agile production environment. Additionally, increasing focus on sustainability practices can draw in international partners looking for environmentally conscious manufacturers. By embracing these changes, the Chinese manufacturing sector can not only overcome its current hurdles but also ensure a robust, innovative future in the global market for metal parts.

The Chinese metal manufacturing sector is on the cusp of significant growth as trends in the global market evolve. Recent discussions at the Antaike 2025 Non-Ferrous Metal Market Conference highlighted key dynamics shaping the industry. Particularly, the increasing demand for lithium—a key component in batteries for electric vehicles and renewable energy storage—is expected to drive innovation and production capacity in China. This surge in lithium processing aligns with global shifts towards sustainable technology, positioning Chinese manufacturers as critical players in the supply chain.

Furthermore, advancements in CNC machining demonstrate China's commitment to modernizing its manufacturing capabilities. As more industries seek precision and efficiency, China's ability to harness technology and skilled labor will be crucial. Reports indicate that the CNC machine tool industry is evolving rapidly, expanding its market reach and competitive edge. With a stable macroeconomic outlook, supported by positive indicators from the first quarter of 2024, Chinese metal manufacturing is poised to capitalize on both domestic and international opportunities, reinforcing its status as a leader in the global market.

| Year | Production Volume (in million units) | Export Value (in billion $) | Market Share (%) | Investment Growth (%) |

|---|---|---|---|---|

| 2021 | 120 | 40 | 35 | 5 |

| 2022 | 130 | 45 | 37 | 7 |

| 2023 | 145 | 50 | 39 | 8 |

| 2024 (Projected) | 160 | 55 | 42 | 10 |