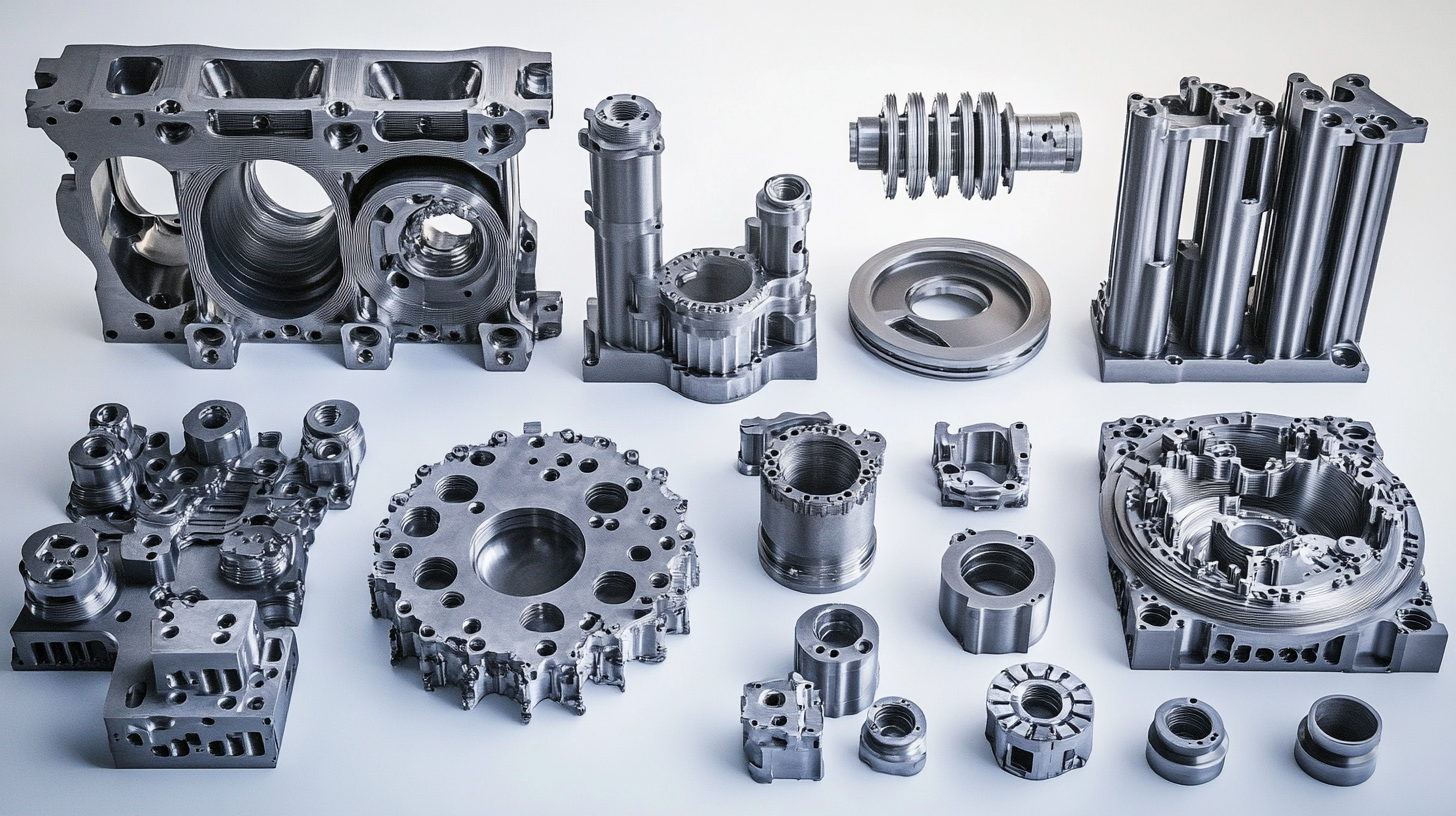

In an era where precision manufacturing is more critical than ever, the global landscape of investment casting foundries is undergoing a transformative shift, largely driven by advancements in technology and China's burgeoning industrial capabilities. Investment casting foundries play a pivotal role in the production of complex metal components that meet the exacting standards required across various sectors, including aerospace, automotive, and medical devices. As these foundries in China continue to expand their reach, they are not only enhancing their operational efficiency but also setting new benchmarks for quality and innovation in the industry. This blog delves into the thriving investment casting foundry sector in China, exploring how these facilities leverage cutting-edge techniques and robust supply chain networks to lead the charge in precision manufacturing on a global scale.

In recent years, Chinese investment casting foundries have made remarkable strides in global markets, solidifying their position as leaders in precision manufacturing. According to a report by MarketsandMarkets, the global investment casting market is projected to grow from USD 14.1 billion in 2020 to USD 22.7 billion by 2025, with Asia-Pacific, notably China, expected to dominate this growth. The rapid advancement in technology and production capabilities has allowed these foundries to fulfill the increasing demand for high-quality components across various industries, including aerospace, automotive, and industrial machinery.

The rise of Chinese foundries can be attributed to their ability to produce complex geometries with exceptional accuracy at competitive prices. A 2022 study by ResearchAndMarkets indicates that the efficiency of Chinese casting processes, particularly in terms of energy consumption and waste reduction, has improved significantly, making them not only cost-effective but also environmentally sustainable. As global manufacturers seek reliable suppliers, Chinese investment casting foundries are emerging as the preferred partners, leveraging their technical expertise and innovation to cater to the evolving needs of the international market. This trend signifies a remarkable transformation in the global manufacturing landscape, positioning China as a hub for precision engineering solutions.

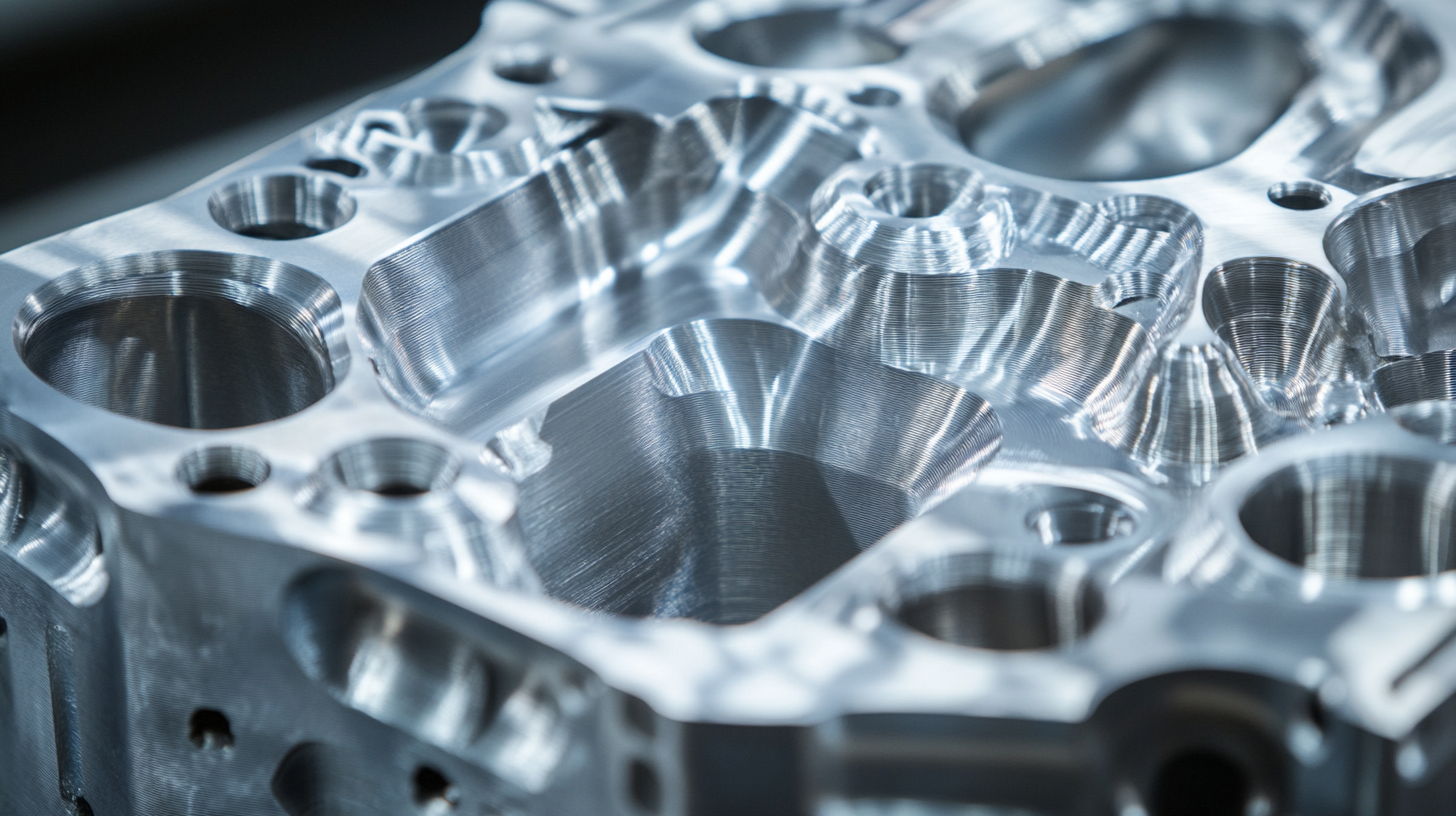

In recent years, the global investment casting market has witnessed significant advancements, particularly driven by innovative techniques emerging from Chinese foundries. As noted in a recent market study by Mordor Intelligence, the investment casting market is projected to reach USD 22.25 billion by 2026, growing at a compound annual growth rate (CAGR) of 5.8%. This growth is largely fueled by the adoption of advanced manufacturing technologies such as 3D printing and computer-aided design (CAD), which enhance the precision and efficiency of casting processes.

Chinese foundries are at the forefront of these innovations, utilizing state-of-the-art equipment and methodologies that ensure meticulous attention to detail. Techniques such as precision wax injection and improved ceramic shell systems have enabled manufacturers to produce complex geometries with tighter tolerances. According to a report by ResearchAndMarkets, nearly 70% of manufacturers prefer investment casting for producing parts that require exceptional dimensional accuracy, highlighting the industry's shift towards precision-oriented methodologies. This technological evolution not only strengthens the competitive edge of Chinese foundries on a global scale but also sets new standards in the precision manufacturing arena.

The global reach of Chinese investment casting foundries plays a crucial role in precision manufacturing across various industries. As industries increasingly rely on sophisticated components, the expertise of Chinese foundries becomes indispensable. These foundries are now setting benchmarks in the production of high-quality castings, particularly in sectors such as automotive, aerospace, and medical equipment, where precision is paramount. The ability of these foundries to deliver customized solutions at competitive prices has empowered many businesses to optimize their supply chains.

Key industries such as electronics and renewable energy also derive significant benefits from Chinese investment casting. The rapid development of electric vehicles and renewable energy systems has led to a surge in demand for precision-engineered components, which Chinese foundries are well-positioned to supply. The integration of advanced manufacturing techniques and adherence to international quality standards further enhance the value proposition offered by these foundries. This expertise, coupled with their strategic geographical positioning, allows them to serve a broad spectrum of global markets, thus reinforcing China's influence in the field of precision manufacturing.

The semiconductor materials market is set to experience substantial growth, with projections indicating a compound annual growth rate (CAGR) of 6.8% from 2025 to 2035. This increase is driven by the rising demand for advanced technologies across various sectors. As Chinese investment casting foundries enhance their precision manufacturing capabilities, they are also prioritizing sustainability initiatives to pave the way for a greener future. Notably, these foundries are integrating eco-friendly practices that minimize waste and reduce their carbon footprint, thus aligning with global sustainability goals.

As the aluminium market continues its steady growth—propelled by demand in the construction, automotive, and packaging industries—Chinese foundries are strategically positioned to meet the increasing need for complex die casting components. The ongoing growth in demand for precision parts offers an opportunity for these manufacturers to lead in both innovation and eco-responsibility.

Tips: To stay competitive, companies should explore partnerships focused on sustainability practices. Embracing AI technologies can also optimize production processes and minimize environmental impact. Additionally, investing in research and development for green materials will be crucial as market trends evolve towards eco-conscious manufacturing.

This pie chart illustrates the distribution of different sustainability initiatives adopted by Chinese investment casting foundries to promote greener manufacturing practices.

The expansion of Chinese investment casting foundries into the global market presents both challenges and opportunities. As these foundries seek to establish a foothold in international markets, they face fierce competition from established players in Europe and North America. The differing regulatory landscapes add another layer of complexity, requiring Chinese companies to navigate stringent quality standards and environmental regulations. Adapting to these requirements demands not only significant investment but also a deep understanding of local market dynamics, which can pose a steep learning curve for many.

However, the opportunities for Chinese foundries are equally compelling. With advancements in technology and manufacturing processes, they have the potential to offer high-quality products at competitive prices. Additionally, the growing demand for precision manufacturing across various industries—such as aerospace, automotive, and medical—creates a fertile ground for expansion. Establishing partnerships with international firms can also provide invaluable insights and access to new markets. By leveraging their strengths and addressing the challenges head-on, Chinese investment casting foundries can position themselves as key players in the global manufacturing landscape.