Lost Wax Casting, a time-honored technique in the world of jewelry making and metal arts, has been revered for its ability to create intricate and detailed designs with exceptional precision. This method, which involves creating a wax model that is later encased in a mold and melted away, allows artisans to explore their creative visions without the limitations often encountered in other casting methods. The versatility and advantages of Lost Wax Casting make it a favored choice among both novice and seasoned craftsmen.

In this outline, we will explore the top ten benefits of Lost Wax Casting for jewelry and metal artisans. This process not only enhances artistic expression but also contributes to the durability and uniqueness of the final product. By delving into the specifics of efficiency, detail, and customization potential, we will highlight how Lost Wax Casting continues to conquer the challenges faced in modern artistry while preserving traditional craftsmanship. Whether you aim to create bespoke jewelry or intricate metal art pieces, the benefits of Lost Wax Casting are manifold, making it an essential technique in the contemporary artisan's toolkit.

Lost wax casting is renowned for its ability to capture intricate details that are often impossible to achieve through traditional casting methods. This technique allows artisans to create highly accurate replicas of their original designs, resulting in jewelry and art pieces that showcase fine textures, delicate patterns, and complex structures. The process begins with crafting a precise wax model, which is then coated with a ceramic shell. Once the shell is heated, the wax melts away, leaving behind a mold that can be filled with molten metal. This ability to reproduce fine detail not only enhances the aesthetic appeal of the pieces but also elevates the craftsmanship involved.

Additionally, the precision afforded by lost wax casting significantly reduces material waste compared to other methods. Artisans can meticulously plan their creations, ensuring that every ounce of metal is utilized effectively. This efficiency allows for the production of custom pieces that can cater to individual preferences while maintaining a high standard of quality. The technique's flexibility also enables jewelers and metal artisans to experiment with different designs and styles, pushing the boundaries of creativity without compromising on accuracy. The combination of detailed craftsmanship and minimal waste makes lost wax casting a preferred method for those dedicated to producing exceptional jewelry and metal art.

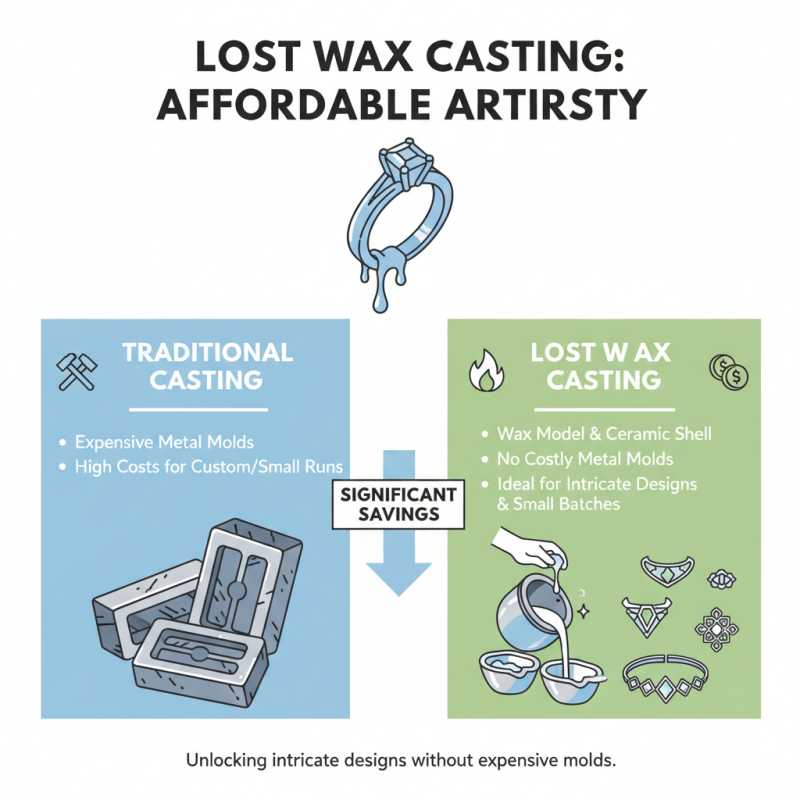

Lost wax casting stands out as a cost-effective method for jewelry and metal artisans, particularly when compared to traditional casting techniques. One of the key advantages is its ability to produce highly intricate designs without the need for expensive molds. The process begins with creating a wax model, which is then encased in a ceramic shell. This eliminates the need for costly metal molds that may be required in other casting methods, resulting in significant savings for artisans, especially when creating custom pieces or small runs.

Additionally, lost wax casting minimizes material waste, further enhancing its cost-effectiveness. The process allows for precise control over the amount of metal used, enabling artisans to create pieces that use only the necessary amount of material. This is in stark contrast to other methods that tend to generate excess waste, increasing production costs. Moreover, the flexibility inherent in the lost wax casting process facilitates rapid prototyping, allowing artisans to experiment with designs and make adjustments quickly without incurring substantial costs. Thus, for jewelry makers and metal craftsmen seeking a budget-friendly approach without compromising on quality, lost wax casting offers a compelling solution.

Lost wax casting, a time-honored technique in the world of jewelry and metal artistry, offers an incredible range of materials that artisans can utilize to bring their creative visions to life. One of the most significant advantages of this method is its adaptability to various metal types, such as silver, gold, bronze, and even less common alloys. This flexibility allows artisans to experiment with textures, colors, and finishes, enabling a wider artistic expression and the ability to cater to diverse client preferences. As artisans work with these materials, they create pieces that are not only visually stunning but also unique in terms of the qualities imparted by different metals.

In addition to traditional metals, lost wax casting can accommodate non-metal materials, such as resins and certain ceramics, expanding the possibilities even further. This versatility provides artisans with the opportunity to blend different material properties, resulting in innovative designs that challenge conventional boundaries. By incorporating a variety of materials into their creations, artists can enhance the thematic and stylistic elements of their work, making lost wax casting an indispensable tool in the realm of contemporary jewelry and metal art.

Lost wax casting has revolutionized the jewelry and metal art industries by significantly enhancing time efficiency in production processes. This technique allows artisans to create intricate designs with relative ease and speed. Unlike traditional methods that require extensive manual labor and time-consuming steps, lost wax casting streamlines the process by enabling artisans to create detailed wax models that can be quickly reproduced. Once the wax model is finished, it can be encased in a mold, which is then heated to melt away the wax, leaving behind a precise cavity for the metal. This method not only reduces production time but also minimizes the risk of human error in the crafting process.

Furthermore, the efficiency of lost wax casting extends beyond just the initial creation of the model. The process allows for multiple items to be cast simultaneously using a single mold, which maximizes the output within a shorter period. Artisans can produce numerous pieces while maintaining high levels of detail, allowing them to fulfill orders more rapidly and meet market demands effectively. This improved time efficiency not only benefits the artisans with increased productivity but also enhances customer satisfaction through quicker delivery times and a broader range of available designs. Thus, lost wax casting stands out as a vital technique for modern jewelry and metal artisans seeking to optimize their production workflows.

Lost wax casting not only serves as a traditional method for creating intricate jewelry and metal art but also aligns with modern sustainability practices. The process begins with crafting a detailed model, typically made from wax, which is then encased in a mold. After the wax is melted away, the mold is filled with molten metal, resulting in a beautifully crafted piece. This method significantly reduces waste, as it allows artisans to use only the necessary amount of material and encourage recycling. Instead of discarding leftover materials, artists can incorporate scrap metal from previous projects, contributing to a more circular economy.

Moreover, lost wax casting minimizes the environmental impact associated with traditional production methods. Unlike mass manufacturing, which often relies on non-renewable resources and generates excessive pollution, this technique can utilize sustainable practices such as sourcing recycled metals. Additionally, the precision of the casting process leads to higher efficiency, resulting in less energy consumption and fewer emissions during production. By embracing lost wax casting, artisans not only create stunning pieces of art but also champion eco-friendly practices that make a positive contribution to the environment.