As we look ahead to 2026, the landscape of casting parts is evolving rapidly. Innovations in materials and techniques are changing how these components are produced. Manufacturers are embracing advanced technologies to improve efficiency and reduce costs. The demand for lightweight and durable casting parts is rising, especially in aerospace and automotive sectors.

New trends focus on sustainability. Eco-friendly materials and processes are becoming essential. This shift is crucial as industries face increasing pressure to go green. However, challenges remain. Adapting to new technologies can be costly and time-consuming.

The growth of 3D printing is influencing casting parts as well. This technology allows for complex designs that traditional methods struggle to achieve. Companies must carefully assess their capabilities to keep pace. Embracing these changes can offer competitive advantages but requires thoughtful implementation.

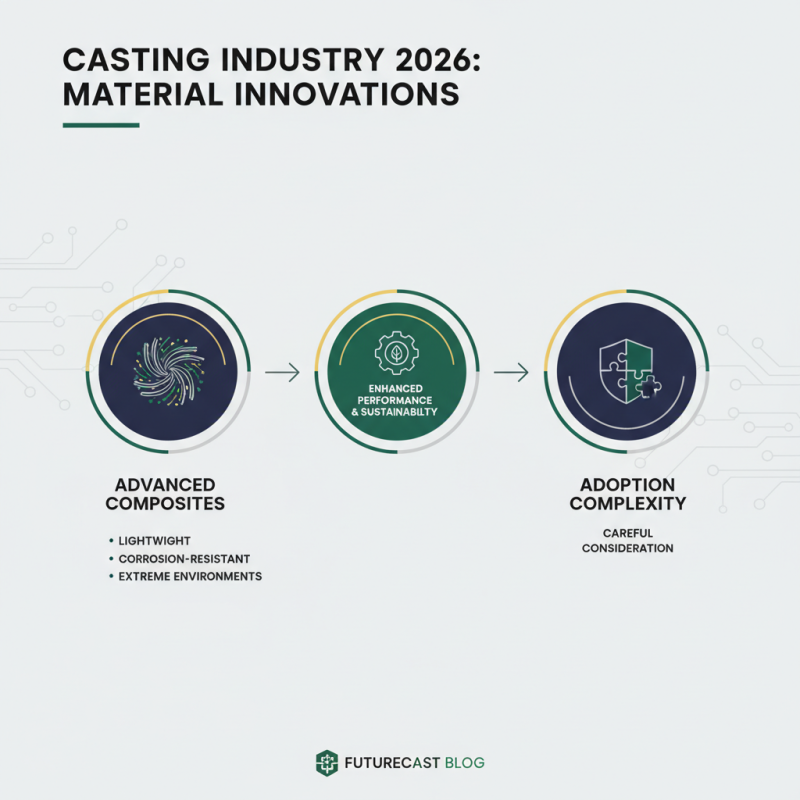

In 2026, the casting industry is set to embrace a range of innovative materials that aim to enhance performance and sustainability. Advanced composites are gaining traction due to their lightweight properties and resistance to corrosion. These materials also promise improved performance in extreme environments, often outperforming traditional metals. However, the adoption of these composites can be complex and require careful consideration.

Bio-based materials are also emerging as viable alternatives. These materials minimize environmental impact and offer unique characteristics that can be tailored for specific applications. While the benefits are clear, the manufacturing processes for these materials can be challenging. There are concerns about consistency and reliability, especially in high-stress applications.

Moreover, recycled materials are increasingly in focus. Using recycled metal can significantly reduce waste and energy consumption. Still, there are questions about the quality and integrity of recycled components. Companies must navigate these challenges while balancing innovation and practicality. The future of casting parts depends on a careful integration of these new materials into existing processes.

Automation and robotics are transforming casting processes in the manufacturing industry.

Advanced robotics can increase productivity significantly.

According to a recent report by MarketsandMarkets, the automation industry is expected to grow by

9.5% annually, reaching over

$280 billion by 2026. This growth reflects a shift toward

smart manufacturing solutions.

Robots are programmed to handle complex tasks. They can operate with precision, reducing human error.

This efficiency is critical in casting operations, where even

small mistakes can lead to costly defects. A study showed that automated systems can improve casting

accuracy by up to

30%. These improvements can significantly reduce waste

and production time.

Sustainability is reshaping the casting industry significantly. According to a recent industry report, over 50% of manufacturers are investing in eco-friendly materials for their casting processes. This is crucial as traditional methods often result in high waste and energy consumption. Companies are learning that minimizing their carbon footprint can lead to substantial long-term savings.

The shift towards sustainable practices also encourages innovation. Techniques such as 3D printing are gaining traction, reducing excess material use. A study indicated that 3D printing can cut waste by up to 70%. Yet, not all manufacturers have adapted. Many still rely on outdated processes, prompting reflections on industry standards. There is a clear need for ongoing education and investment in greener technologies.

Additionally, recycled metals are becoming more popular. In 2022, about 40% of the metals used in casting were recycled, reducing the demand for virgin materials. This shift not only conserves resources but also minimizes environmental impact. However, the transition to using more recycled content presents challenges in quality consistency. Overcoming these hurdles is vital for the industry's sustainability goals.

The landscape of casting is evolving rapidly. Innovative technologies are changing how industries approach manufacturing. Techniques like 3D printing are enabling more complex geometries. This can reduce material waste and production times. However, integrating these advancements is not without challenges.

Another emerging trend is the use of advanced alloys. These materials can enhance durability and performance. Still, they require careful handling and processing. Many manufacturers struggle to adapt their processes to utilize these new alloys efficiently. It’s a time of exploration, but not everything works seamlessly.

Sustainability is also a key focus. Casting processes are becoming greener, yet achieving sustainability is often complicated. Energy consumption and emissions remain significant concerns. Industries must reflect on their practices to truly innovate responsibly. Balancing innovation and responsibility is crucial for a brighter future in casting.

In the casting industry, consumer preferences are evolving rapidly. As sustainability becomes key, manufacturers are exploring eco-friendly materials. Innovations in casting processes enhance precision and reduce waste. With automation on the rise, efficiency is improved. However, adaptation to these changes is often slow. Some companies resist new technologies, fearing loss of traditional craftsmanship.

Tips: Embrace new materials. Look into biodegradable options. They are gaining traction.

Additionally, consumers demand customization. They want products that reflect their unique needs. This trend pushes manufacturers to invest in flexible production methods. Yet, balancing customization with cost-effectiveness remains a challenge. Companies must rethink existing processes to cater to diverse preferences.

Tips: Collect customer feedback. It can guide your innovations. Understand their desires for personalized solutions.

The industry is also influenced by digital transformation. Advanced simulations and AI predict casting results accurately. These tools enhance design and reduce errors. While the benefits are clear, some hesitate to integrate new tech. There’s a fear of complexity and the unknown. A careful approach is essential.